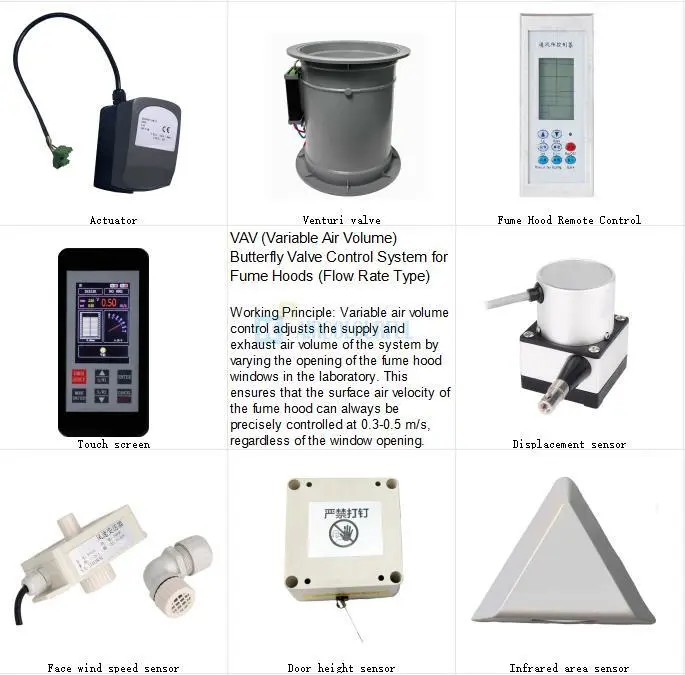

Fume Hood Butterfly Valve Control System Energy Save Remote 0.5m/s VAV Control System

working principle

Single-channel VAV butterfly valve control system:

The system consists of a fume hood controller, a face velocity sensor, an analog fast actuator, a butterfly valve, and a power control box. After the fan duct is installed, as the fume hood operates, the air velocity flowing into the fume hood changes with the adjustment of the fume hood window height. The face velocity sensor transmits the measured air velocity information to the fume hood controller with a response time of less than 1 second. The fume hood controller calculates the face velocity using a closed-loop PID controller, referring to the previously set face velocity value (generally set between 0.4-0.6 s/m), and quickly issues a command to the analog fast actuator to rapidly adjust the butterfly valve angle, increasing or decreasing the valve angle to achieve the set face velocity range. The entire response process does not exceed 1 second. Simultaneously, the fast actuator's operating time (0°-90° operating time) must not exceed 2 seconds to quickly operate the valve and promptly return to the set air velocity value, preventing exhaust gas from the fume hood from overflowing into the room.

Dual-channel VAV butterfly valve control system:

The system consists of a fume hood controller, face velocity sensor, displacement sensor, analog fast actuator and butterfly valve, and power control box. After the fan and duct are installed, when the fume hood is running, as the height of the fume hood window is adjusted, the displacement sensor first detects the height of the fume hood window and quickly adjusts the angle of the fume hood butterfly valve via a signal. When the position of the fume hood window remains unchanged, the face velocity sensor measures the face velocity of the fume hood and makes precise fine adjustments, further finely adjusting the valve angle to return to the initially set face velocity value.

Detail presentation

Product parameter

|

Model |

Single-person single-sided clean bench (horizontal air supply) |

Single-person single-sided clean bench (vertical air supply) |

Double-person single-sided clean bench (horizontal air supply) |

Double-person single-sided clean bench (vertical air supply) |

|

Cleanliness level |

100 level @ ≥ 0.5 μm (US Federal 209E) |

|||

|

Bacteria colony count |

≤ 0.5/dish. hour (φ90mm culture dish) |

|||

|

Average wind speed |

0.3m~0.6/m/s (fast and slow dual speed) |

|||

|

Noise |

≤ 62dB (A) |

|||

|

Vibration half-peak value |

< 0.5um (x.y.z direction) |

|||

|

Illumination |

≥ 300LX |

|||

|

Power supply |

AC single phase 220V/50Hz |

|||

|

Power consumption |

200W |

400W |

400W |

800W |

|

Weight |

≤85kg |

≤150kg |

≤150kg |

≤250kg |

|

High efficiency filter specifications and quantity |

695x600x50x① |

865x558x50x① |

1135x600x50x① |

1355x558x50x① |

|

Fluorescent lamp/UV lamp specifications and quantity |

20Wx①/20Wx① |

20Wx①/20Wx① |

30Wx①/30Wx① |

40Wx①/40Wx① |

|

Applicable number of people |

Single person single side |

Single person single side |

Single person single side |

Single person single side |

|

Dimensions |

850x580x1600mm |

1050x680x1600mm |

1300x580x1600mm |

1540x680x1600mm |

|

Work area dimensions |

700x400x500mm |

870x620x520mm |

1150x400x500mm |

1360x620x520mm |

FAQS