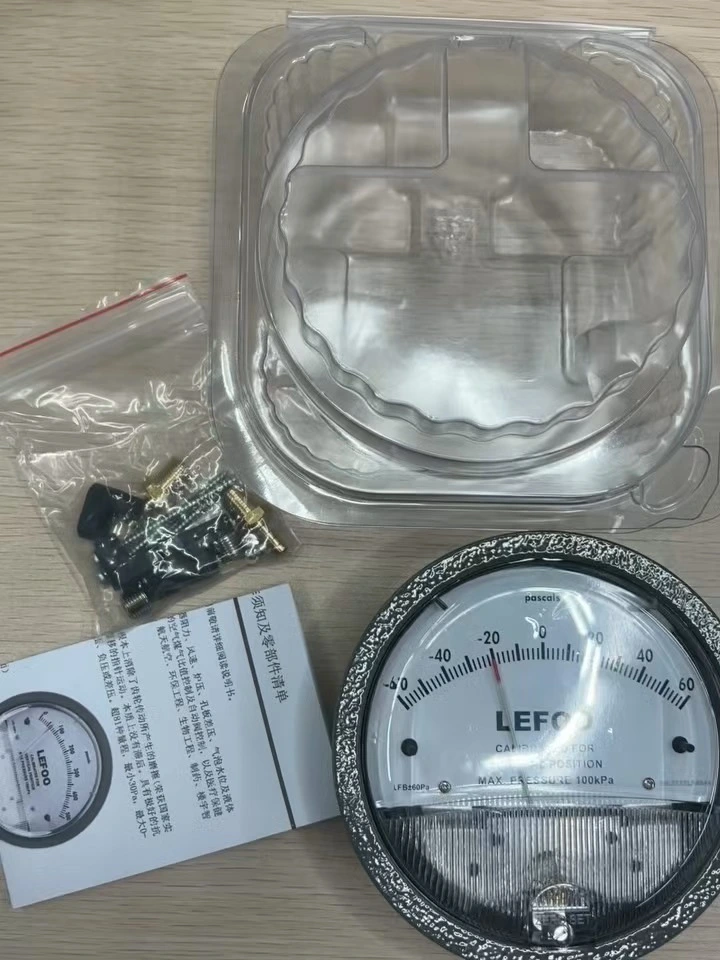

Mini Differential Pressure Gauge

Pointer-type differential pressure gauge

A typical structure includes a case, dial, hands, pressure interface, and transmission mechanism. The dial usually indicates the pressure difference range, with units typically in Pascals (Pa), kilopascals (kPa), or millimeters of water column (mmH₂O).

Digital differential pressure gauges

The core components are a pressure sensor, a signal processing module, and a display screen. The screen directly displays the numerical values, and some models support unit switching, peak value recording, or alarm functions.

Selection Considerations

●Measuring Medium: Choose the appropriate material based on whether the medium is gas, liquid, or corrosive, such as stainless steel, plastic, or PTFE.

●Measuring Range and Accuracy: Select the measuring range based on actual differential pressure requirements; units are often kPa or MPa. Common accuracy classes are 0.5 (error ≤ 0.5% of range), 1.0, and 1.6; select a higher class for precision measurement and control.

●Installation Method: Consider whether the dial orientation and connection interface (threaded, flanged) match the site conditions.

●Protection Level: Select the protection level based on environmental humidity, dust, etc., such as IP65 dustproof and waterproof.

●Certification Standards: Confirm whether the product complies with industry standards.

Use and Maintenance

●Pre-installation Inspection: Verify the model and specifications, ensuring the pointer is not deviated from zero; otherwise, recalibrate or replace.

●Environmental Requirements: Install in an environment with a temperature of -10~+60℃, relative humidity ≤85%, and no vibration or pressure pulsation.

●Operating Procedures: High and low pressure connections must not be reversed. When pressurizing, apply high pressure first, then low pressure. Do not exceed the maximum operating pressure on one side.

●Installation Requirements: Install vertically and keep it level with the pressure tap to avoid additional errors introduced by liquid level differences.

●Regular Maintenance: Check the smoothness of the transmission mechanism and the sealing of the joints to reduce the risk of leakage and corrosion.

FAQS