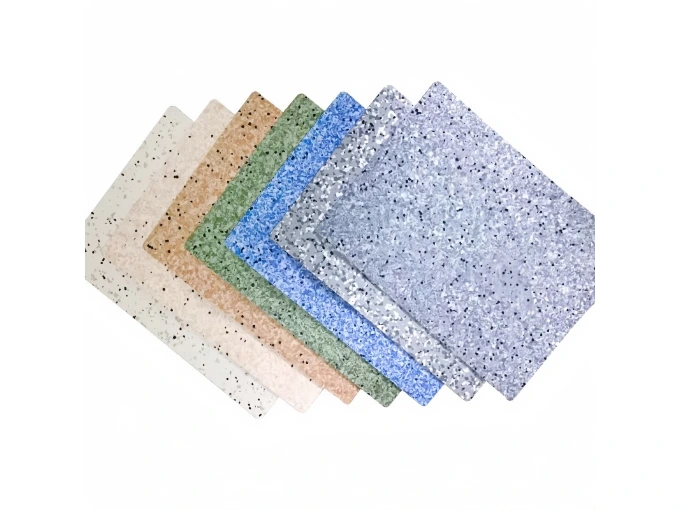

The preferred material for clean room flooring: vinyl flooring

Clean room vinyl flooring is a high-performance floor material that meets the requirements of clean room environment. It is widely used in electronic manufacturing, biomedicine, precision instruments and other fields that have strict requirements on environmental cleanliness, anti-static, antibacterial and other properties.

High flatness and cleanliness

● After laying, it has good flatness, which can ensure that there are no gaps and dust accumulation on the ground, and reduce cleaning dead corners.

● The use of seamless splicing technology can effectively prevent dust and bacteria from accumulating in the gaps, making the cleaning work of the clean room more convenient and maintaining a high degree of cleanliness.

Easy to clean and maintain

● Good wear resistance can reduce the frequency of daily maintenance such as waxing and cleaning, and reduce daily maintenance costs

Chemical and physical stability

● Corrosion resistance: Strong resistance to acids, alkalis, solvents (such as alcohol, acetone) and grease, suitable for environments exposed to chemicals such as laboratories and electronics factories.

● Some models have static conductive or anti-static functions (resistance value 10^6~10^9Ω) to prevent static electricity from damaging precision instruments or products.

Convenient construction

● PVC flooring is green and environmentally friendly, fire-retardant, sound-absorbing and noise-proof, acid- and alkali-resistant, thin and light, and has advantages in building load-bearing and space saving.

● The roll laying or self-leveling process can be completed within 48 hours (including base treatment), reducing the downtime of the clean room.