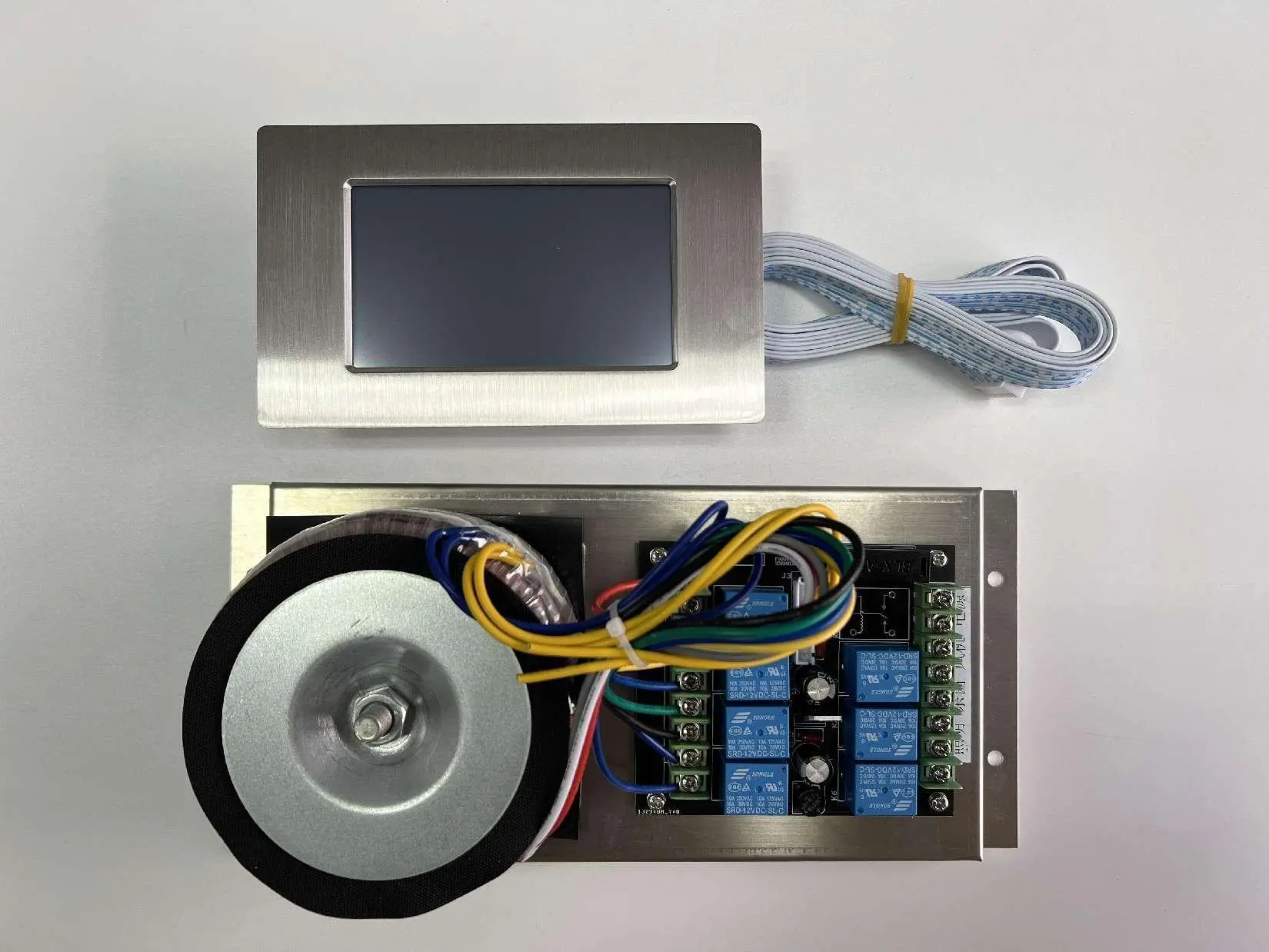

laminar flow hood/workbench controller (for AC fans)

Core Functions

●Fan Speed Adjustment: The AC fan speed can be precisely adjusted via the controller, achieving continuous adjustable fan speed within the working area (e.g., 0.35-0.54 m/s) to meet the cleanliness requirements of different processes.

●Stable Operation: Maintains a constant fan speed, avoiding fan speed fluctuations caused by voltage fluctuations or load changes, ensuring laminar flow stability.

●Status Monitoring: Monitors fan operating status in real time (e.g., speed, current, voltage) and provides feedback on abnormal information (e.g., overload, undervoltage, overheating) via indicator lights or a display screen.

●Safety Protection: Integrates overload protection, short circuit protection, and phase loss protection functions to prevent fan damage due to malfunctions and extend equipment lifespan.

Control Principle

●Signal Input: The controller receives wind speed setting signals from the operation panel (e.g., knob, touchscreen) or external systems (e.g., PLC, DCS).

●Signal Processing: The built-in microprocessor (MCU) processes the setting signal, converting it into a corresponding PWM (Pulse Width Modulation) signal or voltage signal.

●Fan Drive: The PWM or voltage signal is sent to the AC fan drive module (e.g., frequency converter, voltage regulator) to adjust the fan input power and achieve speed control.

●Feedback Adjustment: The fan's built-in encoder or current sensor provides real-time feedback of the speed signal. The controller performs closed-loop adjustment based on the deviation between the feedback value and the set value to ensure wind speed accuracy.

Key Features

●High-Precision Control: Employs a closed-loop control algorithm, with wind speed fluctuations typically ≤±5%, meeting ISO Class 5 (Class 100) cleanroom requirements.

●Strong Compatibility: Supports various AC fan models (e.g., single-phase/three-phase asynchronous motors), covering a voltage range of 110V-380V and a frequency of 50/60Hz.

●Energy-Saving Design: Utilizes variable frequency speed control technology, reducing fan energy consumption by 30%-50%, aligning with green manufacturing trends.

●Modular Structure: The controller adopts a standardized modular design, facilitating installation, maintenance, and upgrades, and supporting parallel operation of multiple controllers.

●User-Friendly Human-Machine Interface: Equipped with an LED display or touchscreen, providing real-time display of wind speed, operating status, and fault codes, offering simple and intuitive operation.